During SNEC exhibition, TOPCon encapsulation solutions obtained the world's first batch of IEC 63556 related standards based on the photovoltaic material product application scene weather resistance "National product preferred" test certificate jointly issued by the National Solar photovoltaic Product Quality Inspection and Testing Center (hereinafter referred to as CPVT) and Huaneng Clean Energy Institute. The certificate is not only the authority of the Betterial technology innovation ability of the full affirmation, but also for its products in the complex and changeable environment to maintain efficient and stable operation of the strong proof.

The "National Product Selection" weather resistance test certificate for all application scenarios issued by CPVT is based on relevant IEC 63556 standards, and carries out a comprehensive and rigorous sequence simulation test for the weather resistance of photovoltaic materials under various application environments such as "full spectrum comprehensive aging test, deep blue ocean high, low latitude, desert hot and dry, polar ice and snow, ecological lakes". The encapsulation materials used in TOPCon modules and composite frame weatherproof coatings and other products, with its excellent weatherability, after a series of rigorous tests successfully passed the full sequence test, becoming one of the first photovoltaic material enterprises in the world to obtain the certification.

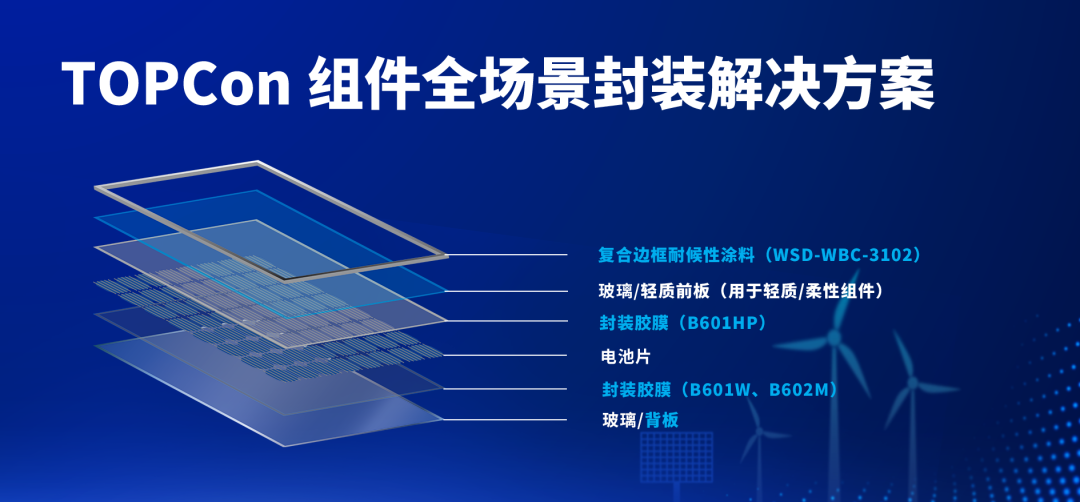

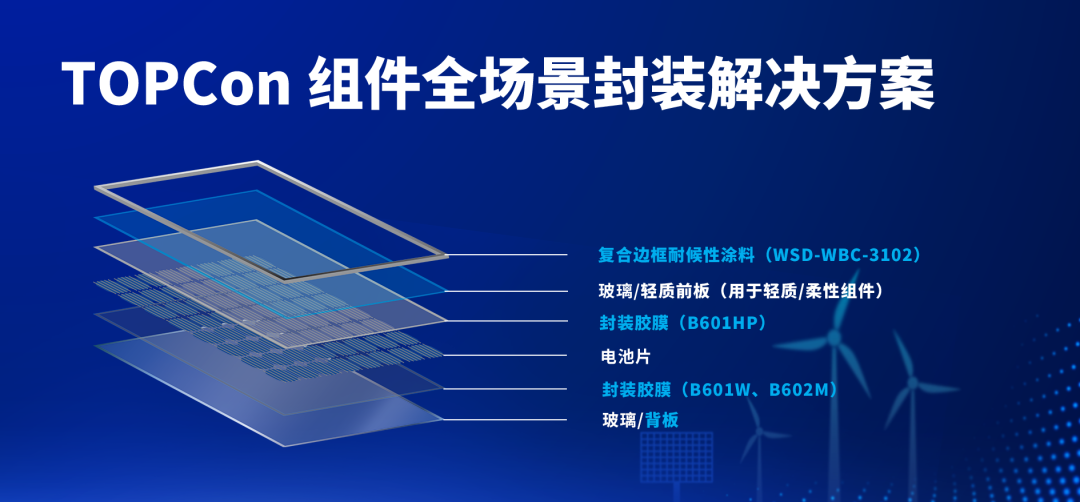

As a leading enterprise in the field of photovoltaic encapsulation materials, Betterial has been committed to providing efficient and reliable encapsulation product solutions for the industry for a long time. Among them, TOPCon module full scene encapsulation solution as one of the star products of Betterial, the use of unique anti-acid anti-polarization formula and advanced technology process, in corrosion resistance, weather resistance, anti-polarization and other aspects of the industry leading level, measured DH2000 attenuation is less than 2.5%, BOM cost can be saved about 25%. For different application scenarios, Betterial provides a variety of TOPCon encapsulation solutions to meet customer customization needs. The newly launched TOPCon single-glass high-reliability dual-EVA encapsulation solution has met the test requirements of Chint, Tongwei, Jinko and many other leading customers, and some customers have achieved batch delivery, actively enabling module customers to reduce cost and increase efficiency.

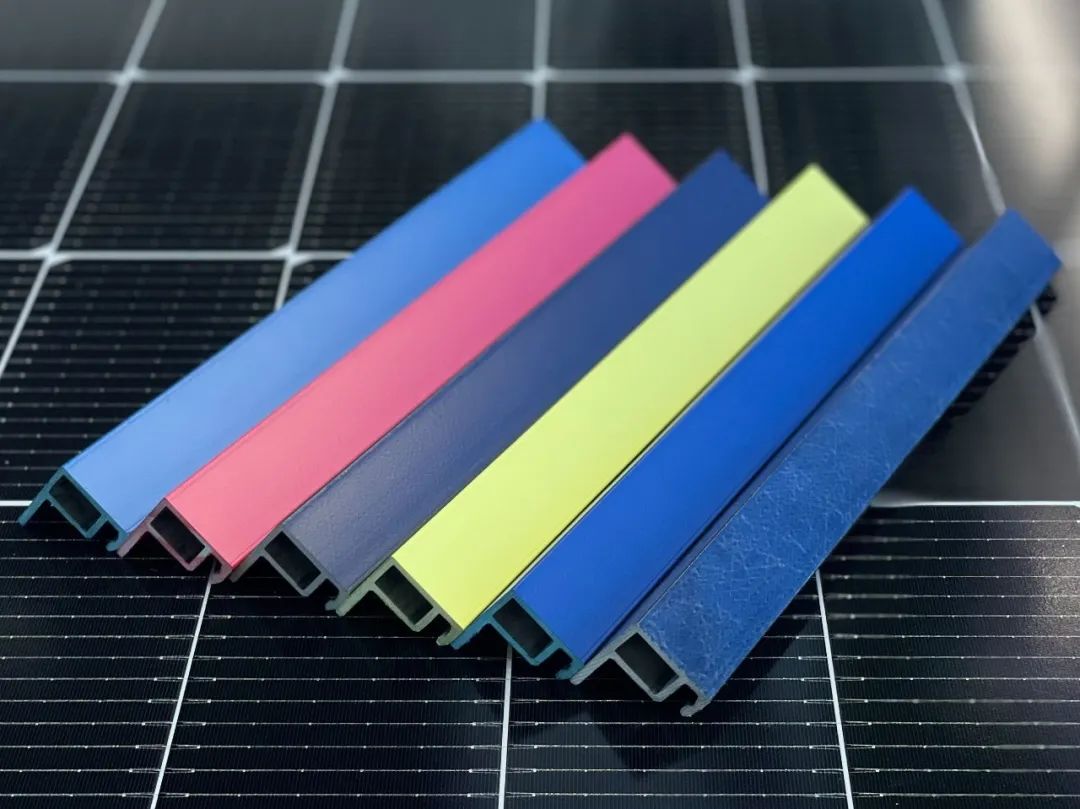

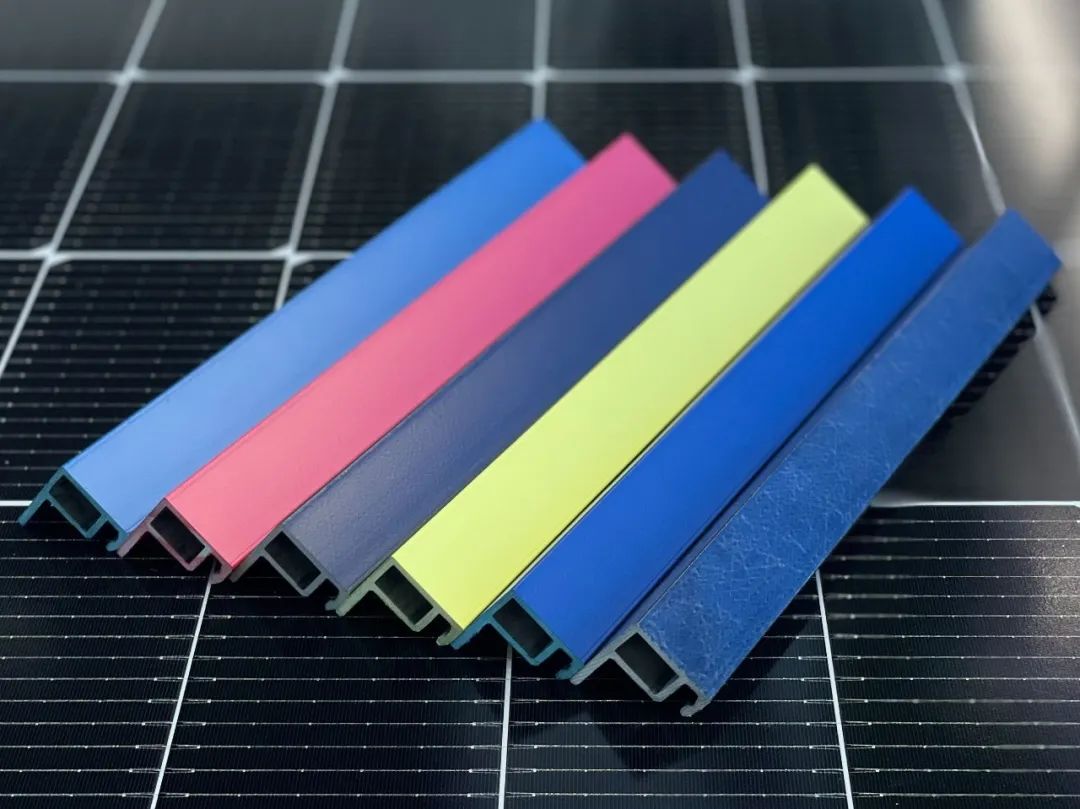

The composite frame weather resistant coating independently developed by Betterial realizes an organic and inorganic hybrid system by introducing silicone and condensation technology, which makes the Si-O-Si structure in the coating perform well in weather resistance and aging. At the same time, the introduction of organic structure also improves the adhesion and processability of the coating, so that the coating can better combine with the photovoltaic composite border material, forming a strong protective barrier, to ensure that the composite border products can effectively resist the erosion of different acidic, alkaline and other harsh environments, and also maintain stable product performance during long-term use. For the long-term reliable operation of photovoltaic products to provide protection.

In order to ensure the stability and reliability of products, in addition to TOPCon encapsulation products, Betterial has also actively laid out the full scene field verification of encapsulation solutions such as HJT, perovskite and lightweight modules. The technical research and development team closely monitors the performance of the empirical products in various extreme environments, and continuously optimizes the product formula and structure through long-term data collection and analysis, striving to provide more stable and reliable encapsulation product solutions for global customers, and help the high-quality development of the global photovoltaic industry!