On June 15, 2024, SNEC2024 International Solar Photovoltaic and Smart Energy (Shanghai) Conference and Exhibition, a grand event of photovoltaic industry attracting worldwide attention, came to a successful end in Shanghai National Convention and Exhibition Center. With full-scene photovoltaic module encapsulation solutions, zero-carbon smart city "photovoltaic +" scenario encapsulation solutions, composite border weatherproof coating, directional reflection gap film, high insulation diffuse reflection gap film and other latest products as well as energy storage insulation material solutions, the world's first [LightUP] light enhanced front sheet. With global PV colleagues, discuss the new development trend of the industry.

The latest lightweight material, the world's first

On the first day of the exhibition,Betterial released LightUP the lightweight reinforced front sheet, and held the certification ceremony of "TUV Rheinland IEC 62788-2-1 certification", the atmosphere lit up the audience! [LightUP] Light reinforced front plate adopts polymer composite technology, by special glass fiber, resin, functional additives crosslinking riveted, in the impact resistance, weather resistance, wear resistance, corrosion resistance, light transmission and other convenient performance, with stable product performance, high material utilization, simple process, can shorten the module process, effectively improve the module processing efficiency, The product has a long shelf life and can be stored at room temperature, reducing the inventory pressure of customers.

0BB module encapsulation solution

Betterial's "0BB skin film encapsulation solution", using low-gram weight EVA skin film, product performance is stable, light transmittance ≥92%, fog ≤3%, thermal shrinkage ≤2.5%. High laminating yield: excellent laminating yield, good appearance EL after laminating, no virtual bubble problem. 0BB exclusive encapsulation scheme, double IEC test attenuation is less than 3%, TC600 no appearance EL bad. With lower LCOE, 0BB improves module power, low encapsulation cost, module silver saving, to achieve cost reduction and efficiency.

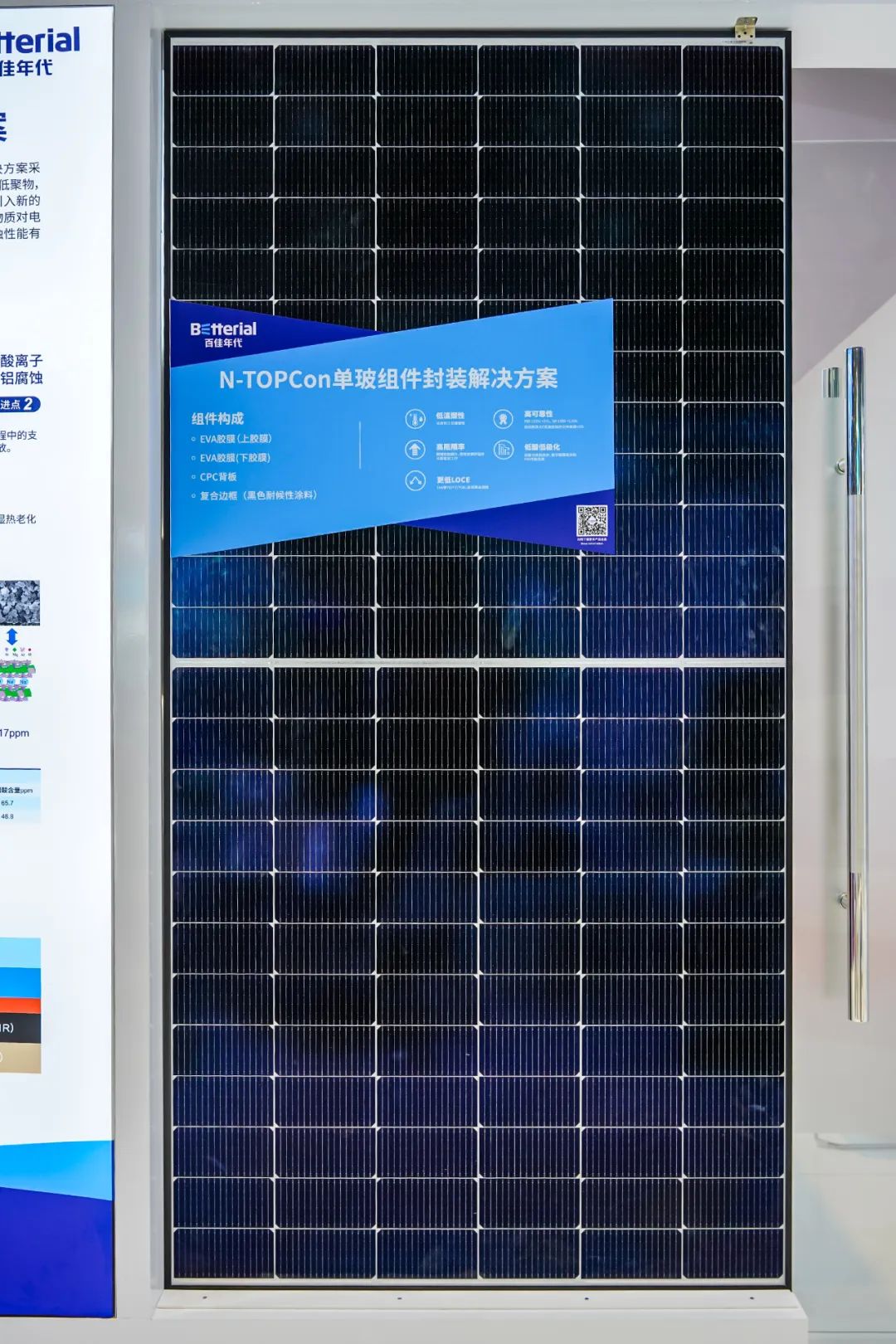

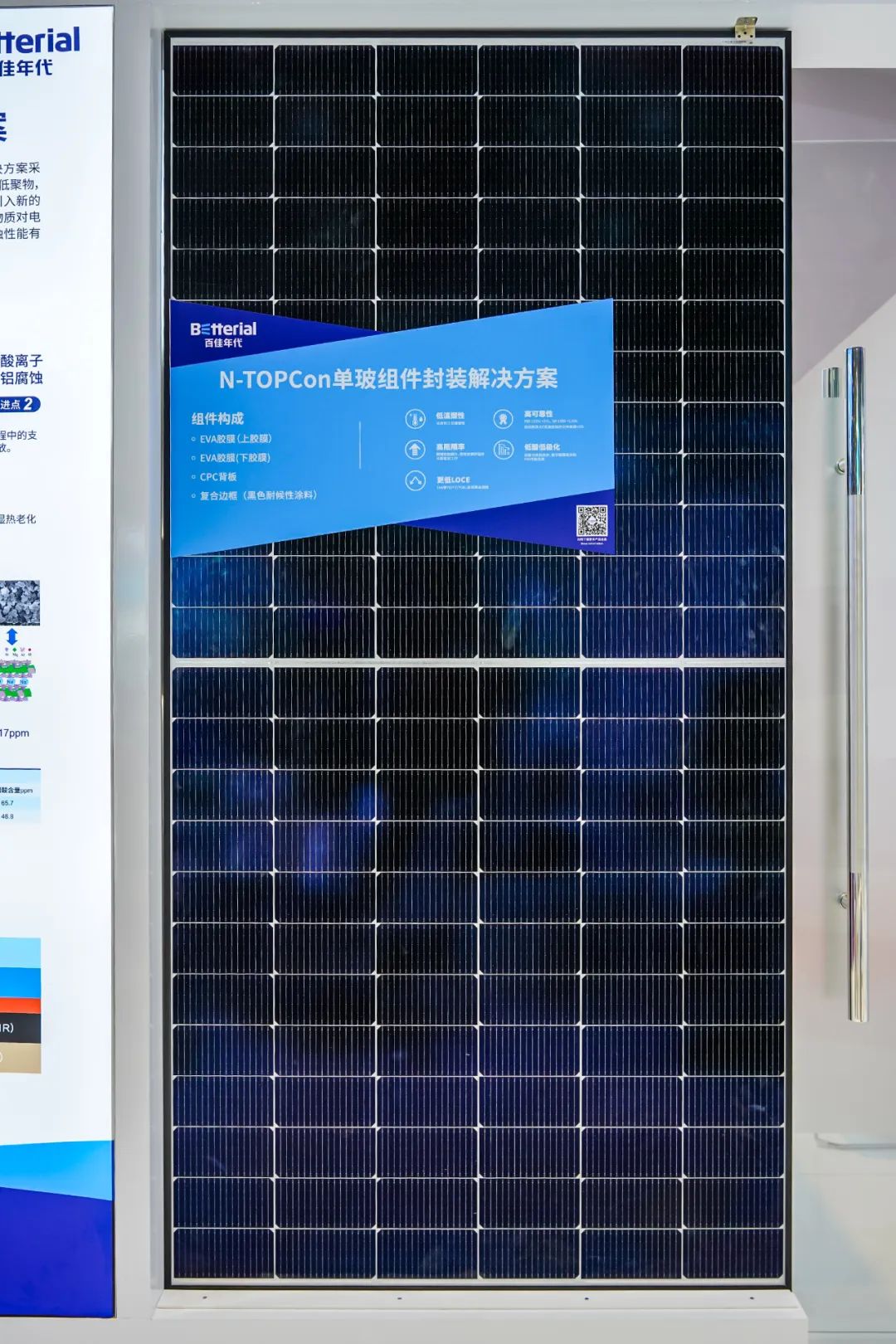

TOPCon single glass module double EVA encapsulation solution

TOPCon single glass module double EVA encapsulation solution, the use of high permeability anti-corrosion EVA film, with BPF back sheet encapsulation solution, the product introduces hydrophobic silane coupling agent oligomer, with good hydrophobicity, effectively delay the water vapor intrusion on the battery surface, product barrier performance is improved. On the basis of the original technology, new additives are introduced to absorb and neutralize the acid ions hydrolyzed by the film and the potassium ions and sodium ions produced by the glass, effectively inhibiting the corrosion of organic acids and other substances on the battery, and reducing the phenomenon of EL blackening. The company's self-made anti-acid masterbatch, compared with the traditional film in the process of wet and heat aging corrosion resistance has been significantly improved, the acid value after PCT is significantly reduced, to protect the long-term stability of TOPCon battery in the single glass encapsulation.

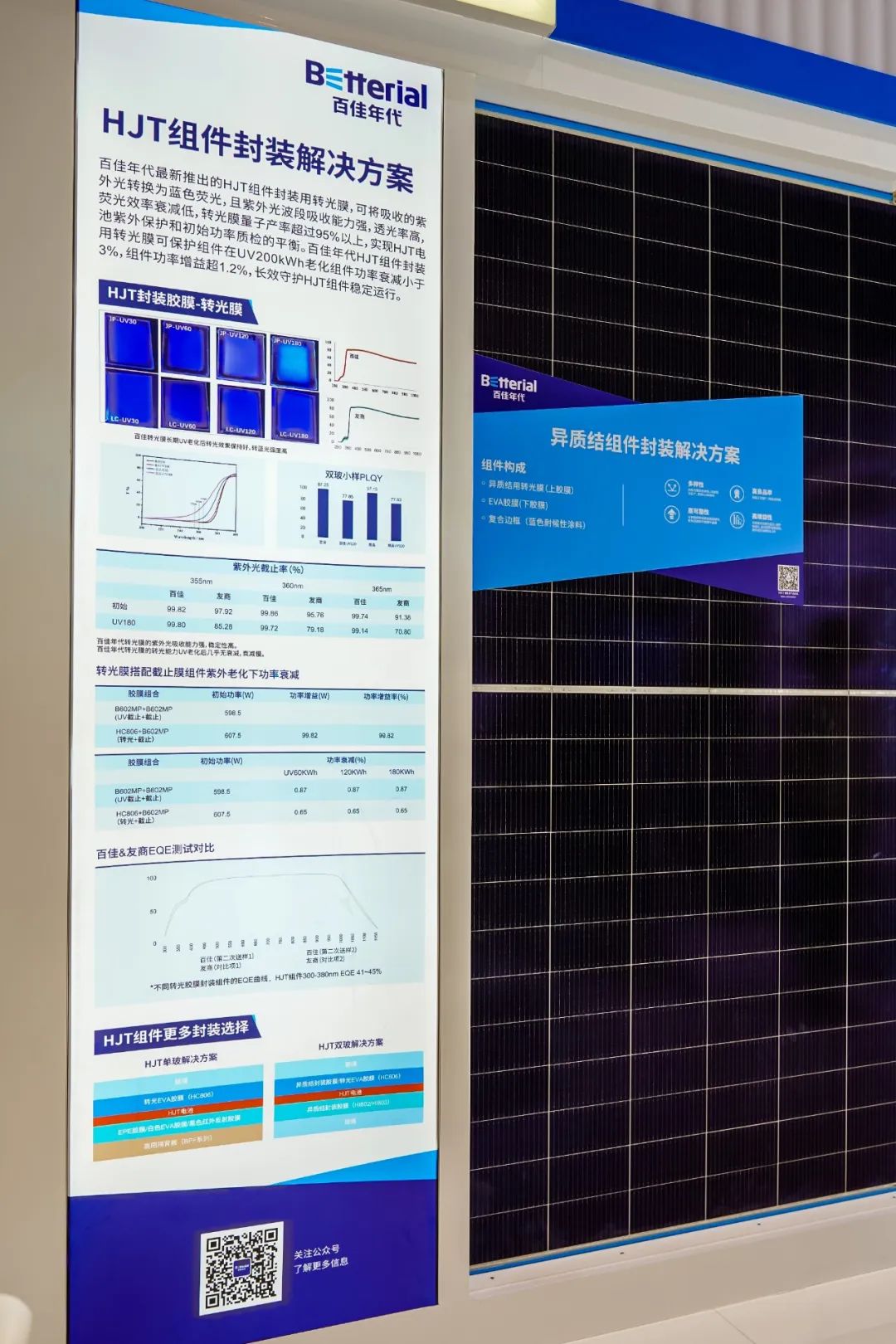

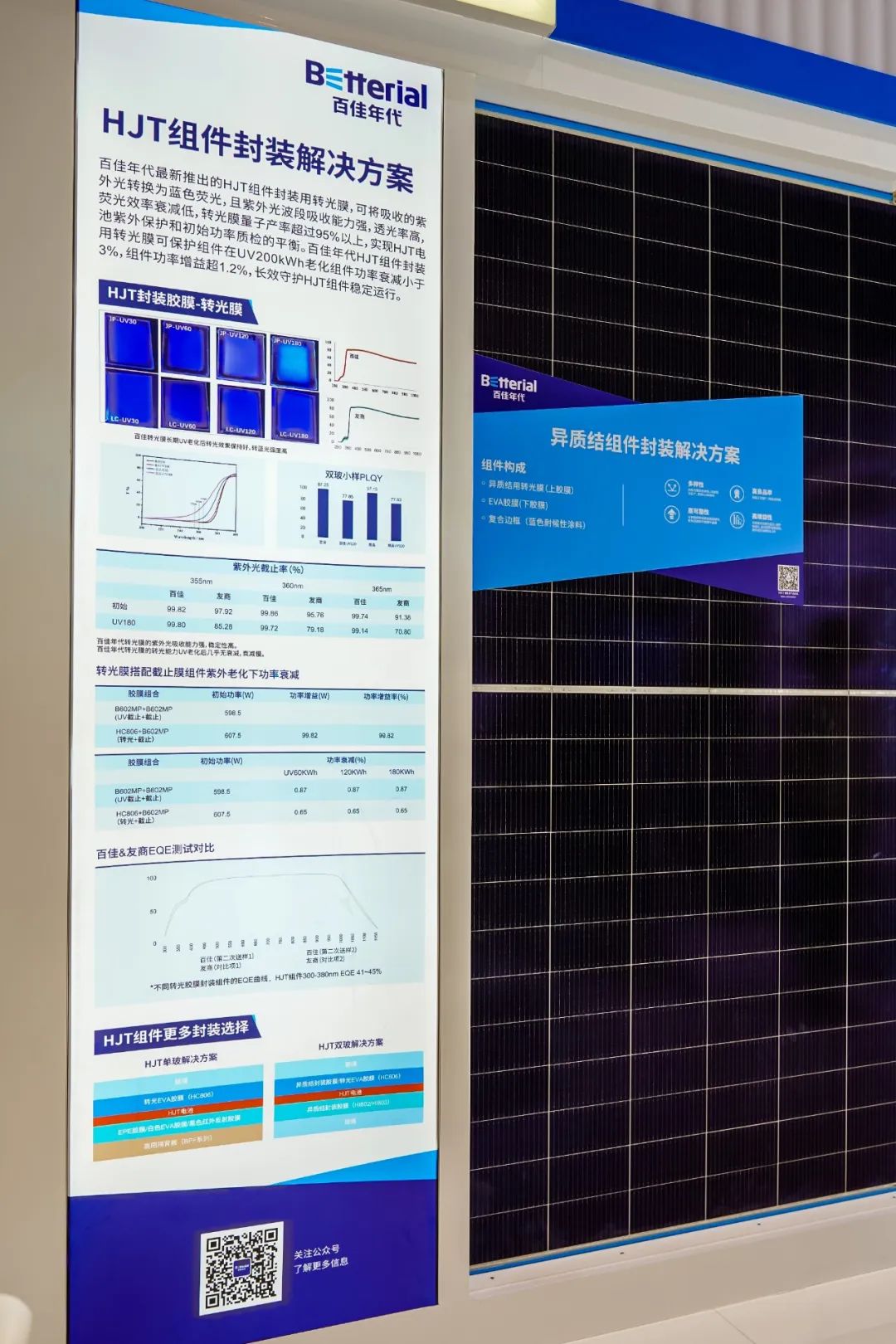

HJT phototransfer film technology scheme

The newly launched HJT module encapsulation with the conversion film, can be absorbed UV light into blue fluorescence, and UV absorption ability is strong, high transmittance, low fluorescence efficiency attenuation, the quantum yield of the conversion film is more than 95%, to achieve HJT battery UV protection and the balance of initial power quality inspection. The rotating light film for HJT module encapsulation can protect modules on UV200kWh aging module power attenuation less than 3%, module power gain more than 1.2%, long-term protection HJT module stable operation.

High reflection all black aesthetic module encapsulation solution

The black high-reflection backplane developed by Betterial adopts double-sided coating product structure, the CPC inner layer is high reflection black and ultra-high reflection black, the reflectivity is 60% and 95%, and the use of high reflection filler greatly improves the reflectivity of the inner layer, and the component power can be increased by 2-4% per 100W.

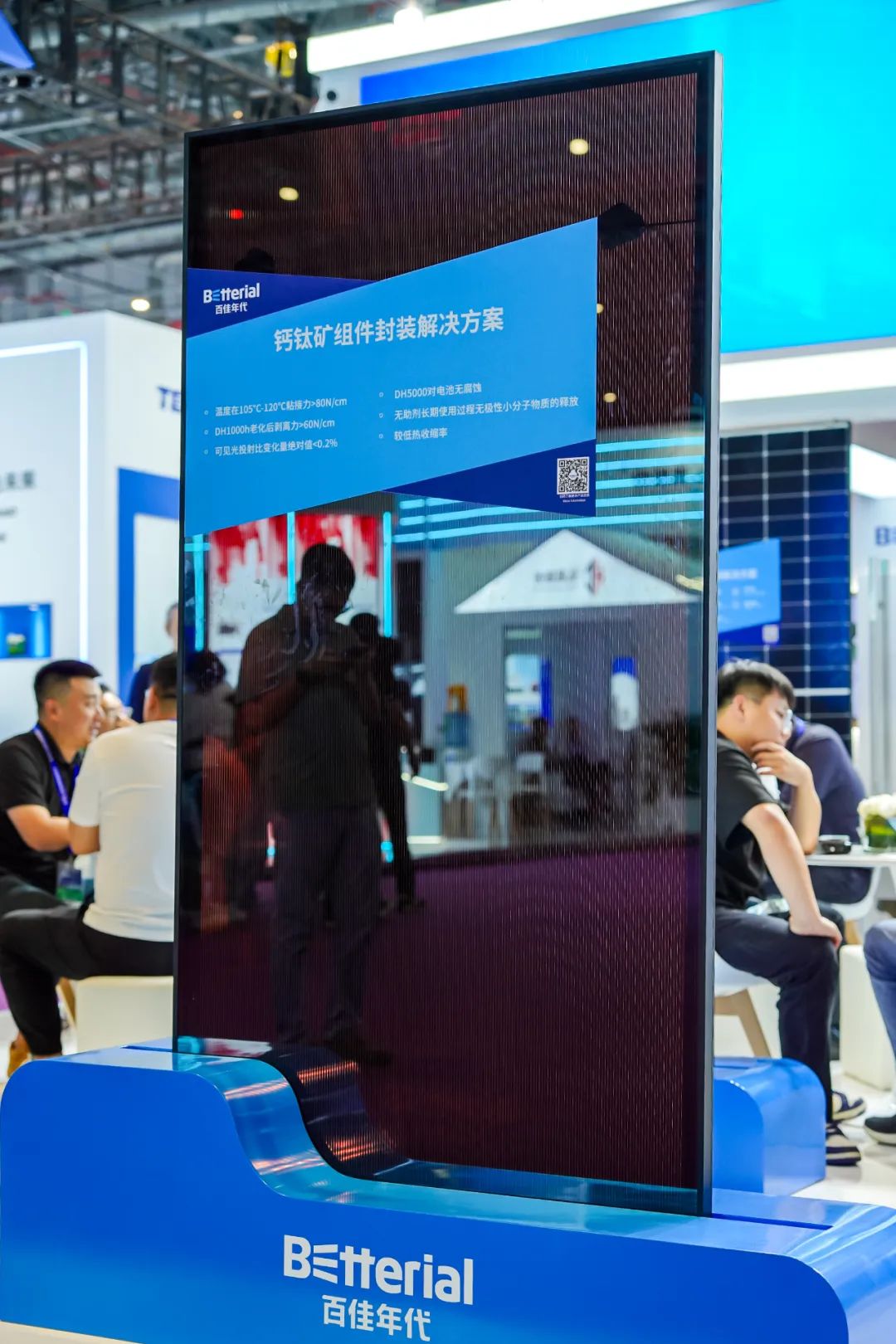

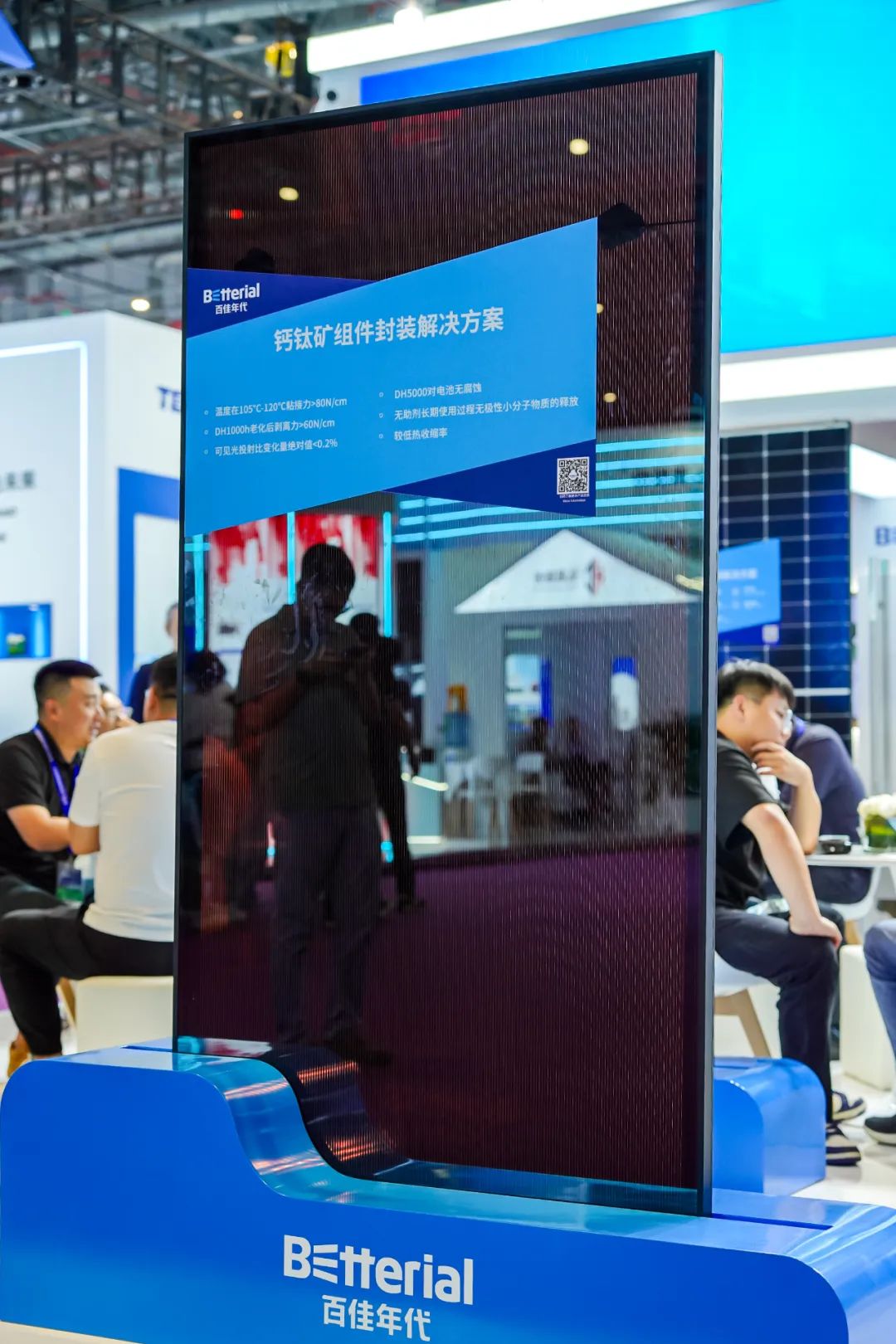

Perovskite module encapsulation solution

Betterial's new generation of perovskite special film can play a better role in protecting sensitive laminated batteries, and provide more support for the stability of perovskite and laminated perovskite modules. At present, the film products have passed the National Inspection Center, Suzhou Meihua and other third party testing certification, and with GCL, Microquanta, Jidian, Wandu and many other head perovskite enterprises for technical docking and sample, and with Longi, Trina, Yaoneng and other customers in the encapsulation of new laminated perovskite batteries for technical cooperation.

More innovative products help the development of the industry

Composite border weather resistant coating: through the introduction of silicone and condensation, to achieve organic inorganic hybrid system, the use of Si-O-Si structure in the coating to meet the weather resistance and aging, organic structure to improve adhesion and processability, with silicon-containing materials to match the weather resistance of fluorine-containing compounds.

Gap reflective film: Betterial’s directional reflection gap film, high insulation diffuse reflection gap film and other latest innovation products, products without metal material, modules without insulation risk, gain over 0.15%.

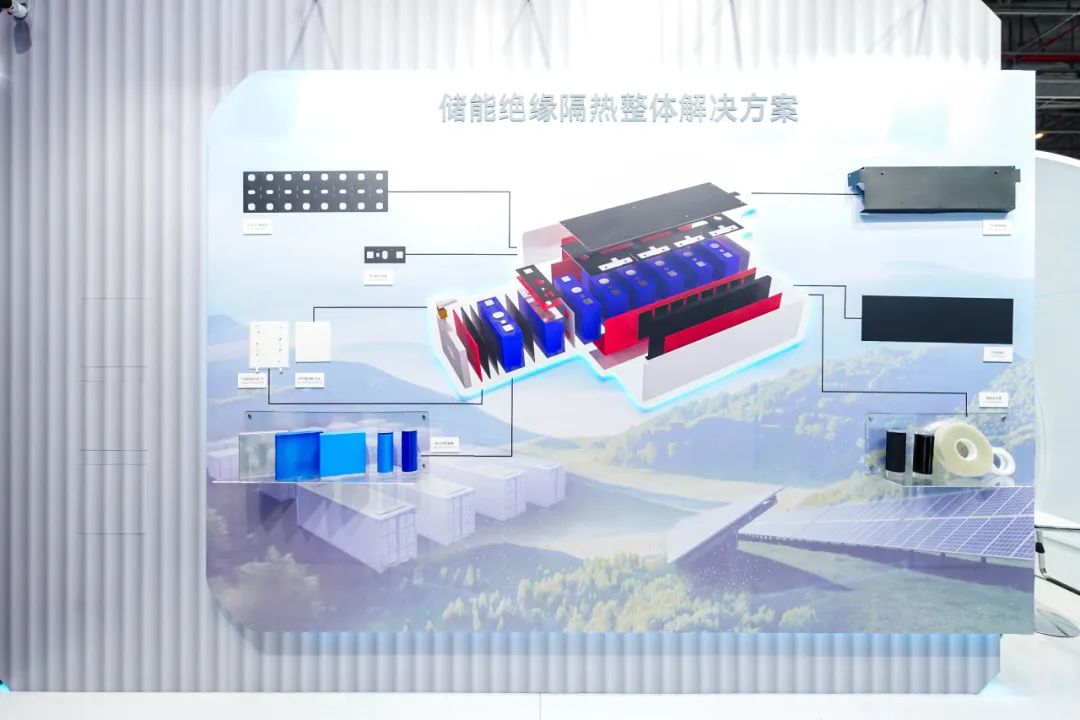

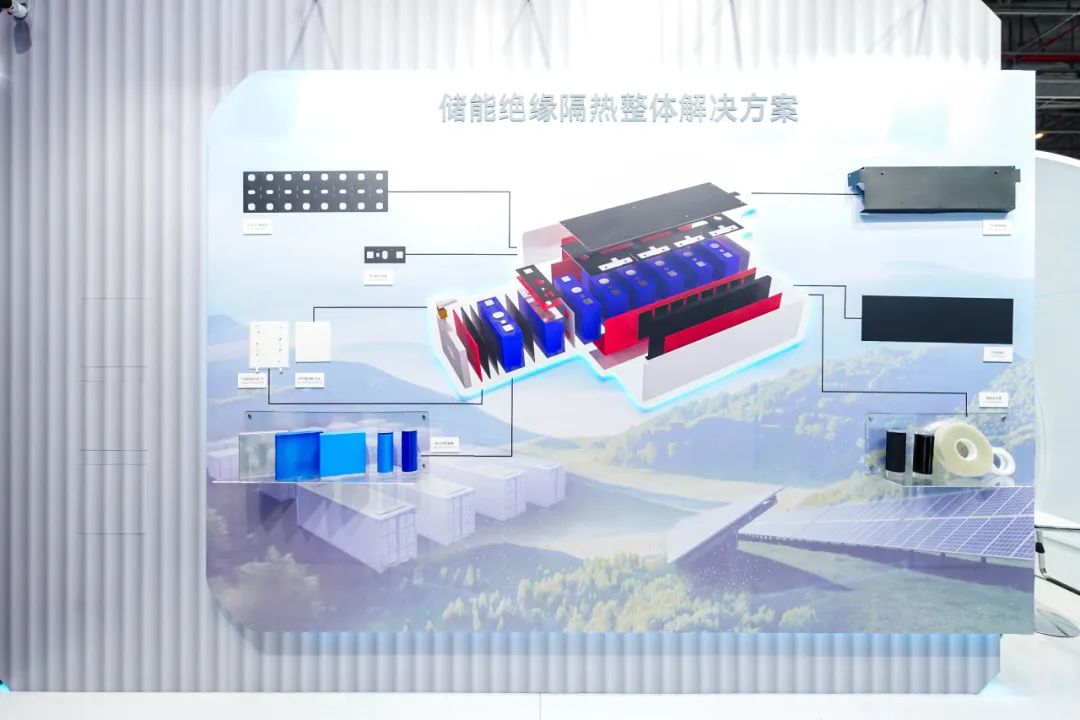

This exhibition with Glades ® energy storage/lithium insulation coating, core insulation tape, PI flame retardant hot pressing film, PC insulation materials, MPP heat insulation board, aerogel heat pad/sheet/sheet and other products, well recognized by the market, boost new energy storage, power battery industry high-quality development.

Innovation achievements on site presentation

Betterial participated in the forum and delivered the keynote speeches "Composite border weatherproof coating System Solution" and "New anti-polarization EVA film for Reliability Encapsulation of N-type batteries". At the same time, at the booth held a number of photovoltaic film, photovoltaic back sheet, light materials and other full-scene encapsulation technology solutions technology presentations.

The certification ceremony of the authority

On June 13, Betterial’s TOPCon special adhesive film was awarded the first batch of IEC 63556 photovoltaic material "National product preferred" all-application scenario weather resistance test certificate by CPVT National Photovoltaic Quality Inspection Center and Huaneng Clean Energy Institute.

On June 15, Betterial's "New anti-polarization EVA film" and "weatherproof coating for composite border" won the "SNEC Ten Highlights" Honor Award issued by the Organizing committee.

Betterial participated in the SNEC2024 exhibition, not only showing the PV module encapsulation solutions and the latest achievements and leading technologies in the whole scene, but also demonstrating its strength and responsibility as a global PV industry leader.

In the future,Betterial will be positioned as the "leader of polymer functional film innovation application", adhering to the core values of "hard work,quality,innovation and responsibility", relying on its own polymer functional film innovation application platform, research platform and innovation force such as Betterial New Materials Research Institute, and embracing change, and working hand in hand with partners through the industry cycle. In order to build a new industrial chain ecology, help achieve the goal of "double carbon", contribute to the strength of Betterial, and promote the healthy development of the global photovoltaic industry!