For every enterprise in the photovoltaic industry chain, reducing cost and increasing efficiency is one of the main tones of product innovation and upgrading. Everyone is thinking about how to make a breakthrough in the problem of reducing costs and increasing efficiency in their own links.

Not long ago, China Photovoltaic Industry Association held the "2024 Photovoltaic Power Generation Project Technical and Economic Forum" in Beijing.Betterial was invited to attend, and demonstrated the latest application of photovoltaic 0BB non-main grid technology of high reliability encapsulant solutions.

0BB technology in 2023, become TOPCon, HJT and other next-generation N-type battery technology metal interconnection process important iterative direction! The technological changes in this grid line have made it possible to achieve a substantial reduction in the cost of silver paste.

Photovoltaic technology brings forth the new, and strives to promote cost reduction and efficiency increase

From MBB to SMBB, technological changes in the grid line have greatly reduced the amount of silver paste consumed, so is it possible to continue to optimize? The 0BB technology provides the answer. The 0BB technology directly eliminates the main grid and optimizes the width and spacing of the secondary grid.Compared with SMBB, 0BB can not only reduce the amount of silver paste, but also reduce the cost of modules. And because the number of thinner welding strips is increased, the circuit loss is reduced and the power of the module is promoted. In addition, by increasing the junction contact points, the power attenuation caused by hidden cracks is reduced.

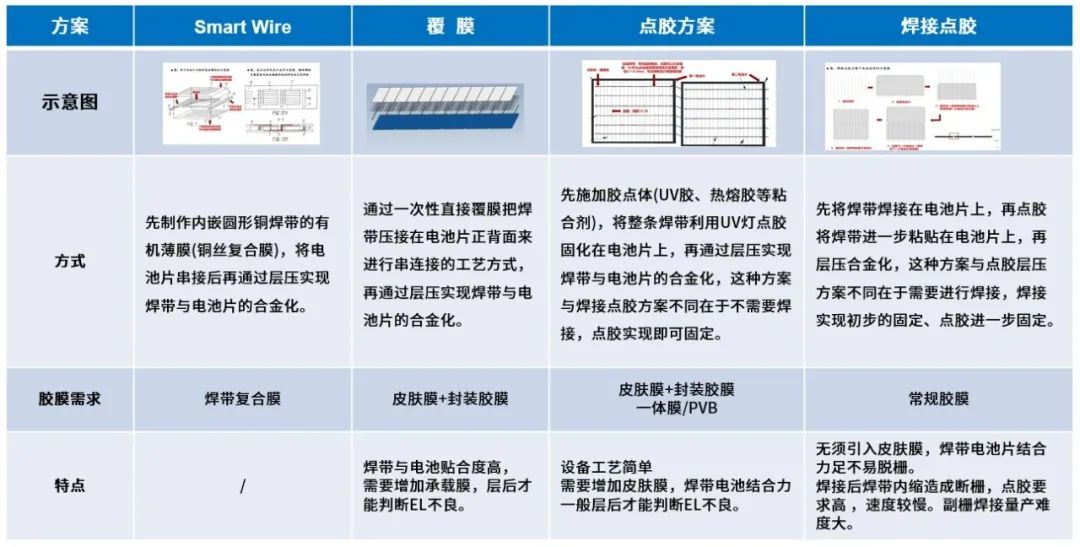

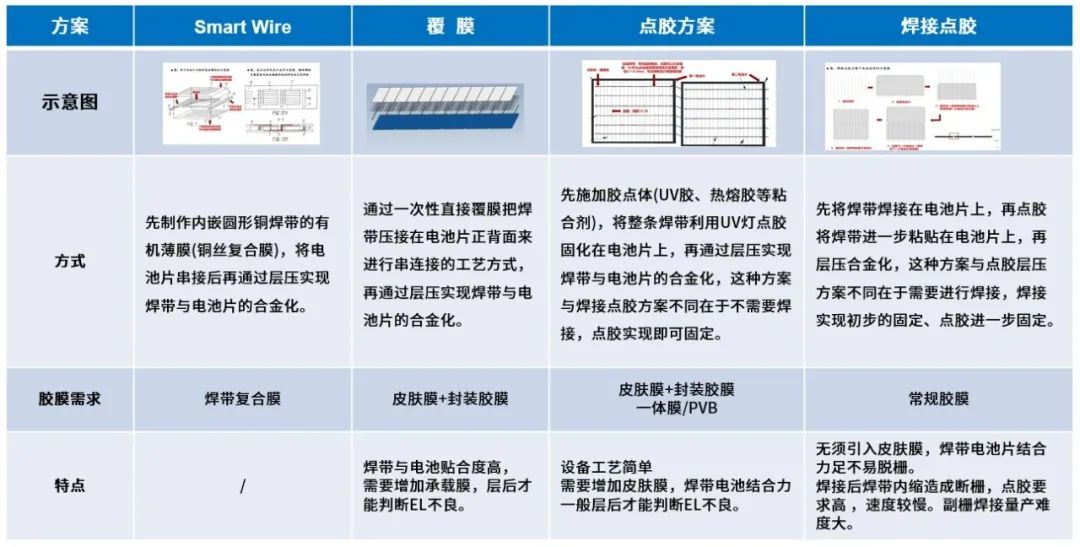

At present, there are four kinds of technology routes in the industry such as Smart Wire, IFC laminating, dispensing and welding dispensing, among which Smart Wire is limited by patent protection, and the technology is only held by individual enterprises. The other three are getting a lot of attention from the industry. As the head company of photovoltaic encapsulant materials, Betterial has already laid out 0BB encapsulant technology, and has mature solutions for IFC laminating, dispensing and welding dispensing.

Grid line "from there to nothing", encapsulant needs new ideas

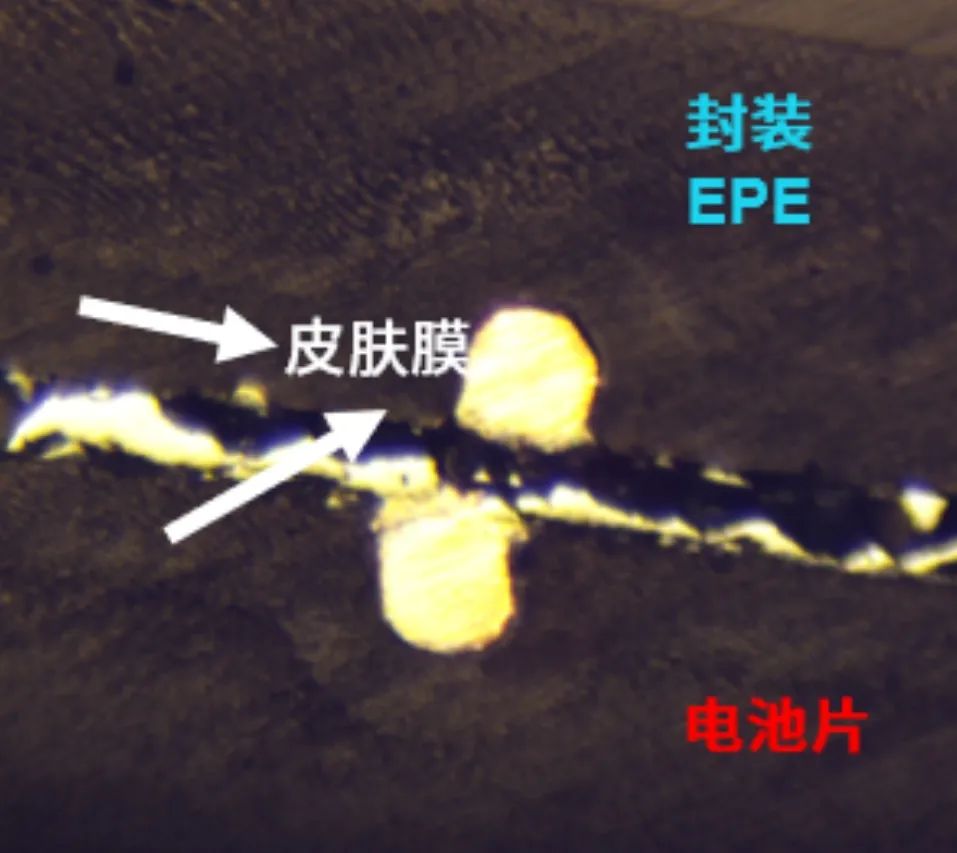

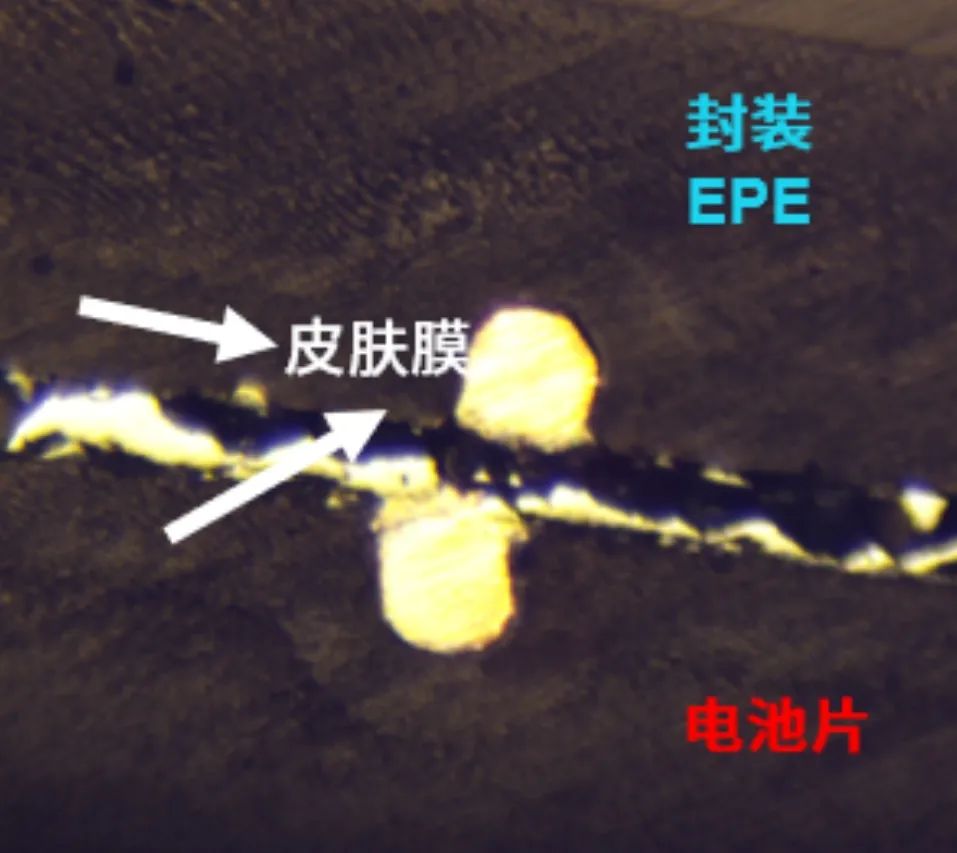

It is understood that the structure of 0BB no main gate technology has a strong particularity.In order to achieve the ideal alloying effect in the process of welding tape and battery lamination, the fluidity of the supporting encapsulant film is required to be low, so that the virtual connection can be avoided.

In response to 0BB technical requirements, Betterial launched the "skin film + low-gram weight EPE film" encapsulant technology, the use of highly bonded modified resin, the fluidity of the film lamination is low, the hardness of the film bond layer is high, while improving the adhesive force of the film and the battery, the lamination process can achieve the perfect encapsulation of the welding belt, effectively improving the yield and product stability of the photovoltaic module process.

Betterial skin film shaping effect verification shows that there is no EL welding and bad appearance after lamination, and TC200 test performance is perfect.

In the process of product innovation and upgrading, these four goals, such as saving silver, thinning, improving efficiency, and high yield, each of which means a huge cost improvement.The 0BB masterless grid technology encapsulant scheme launched by Betterial has obvious advantages in the above aspects.

1-Improing Efficiency

The same version of the 0BB module, Betterial introduced the encapsulant solution can achieve a smaller welding strip, a smaller shading area, and a module power increase of about 0.7%-1%.

2-Saving Silver

It can effectively reduce the battery stock consumption, more stable realization of silver coated copper/copper interconnection technology, reduce the use of silver paste.

3-Thinning

Betterial's skin film technology can achieve low temperature welding, more suitable for battery lamination, and further save the amount of silicon material.

4-High Yield

Betterial's 0BB encapsulant technology is better in the lamination process and welding tape coating performance. It can improve the yield of photovoltaic module process and product stability.

Integrated membrane technology brings more possibilities for photovoltaic cost reduction

In practice, Betterial found that the production cost of the skin film program is high.The process requirements of the low-gram weight film are relatively strict.The module process needs to be laid twice, and the skin film laying will also involve equipment transformation. In order to further reduce the cost of 0BB, based on more than ten years of experience in photovoltaic encapsulant technology, Betterial quickly laid out the "integrated film" encapsulant technology applied to 0BB, and can provide customized "integrated film" encapsulant solutions according to different technical needs of customers.

Among them, Betterial's "light transfer integrated film" encapsulant scheme, the light transfer film and conventional film through the co-extrusion process to achieve one-time preparation, can be different bands of light absorption into visible light, further improve the photoelectric conversion efficiency of the component, but also with low aging stripping force attenuation, UV stability, high process yield characteristics. The PID effect of components can be significantly reduced by laboratory verification.The R&D team will continue to explore in the direction of integrated membrane technology, and is committed to creating product solutions with higher process yield and lower production costs.Technology has no end! With the upgrading of film and equipment technology, the realization of direct encapsulant with conventional film is the primary choice for future 0BB encapsulant to reduce cost.