Recently, "New Quality Productivity" has become a high-frequency hot word in China's photovoltaic industry. As a globally recognized "Next Generation Photovoltaic Cell Technology", perovskite batteries are undoubtedly a typical representative of new quality productivity.Driven by technology iteration and policy, China's perovskite battery industry chain has begun to take shape.But because of the particularity of perovskite structure, encapsulation technology plays a crucial role in its stability. As the first company to achieve small batch delivery of perovskite encapsulate film, Betterial has been committed to the research and development of this technology for a long time, and has made new breakthroughs in perovskite and laminated perovskite encapsulation technology, further promoting the industrialization process.

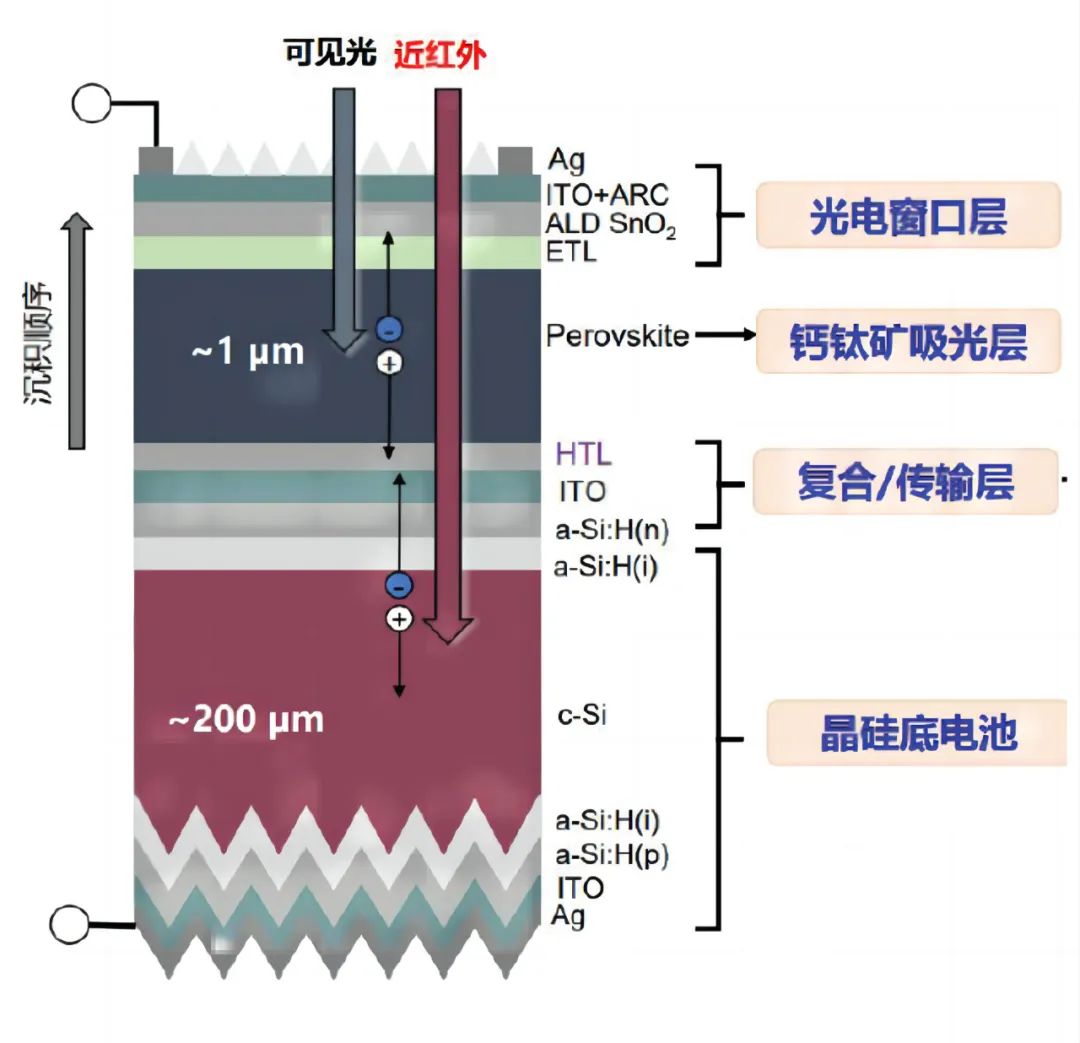

As crystalline silicon cells gradually approach the theoretical efficiency limit of 29.4%, the space for subsequent technological improvement is increasingly limited. In contrast, the theoretical limit efficiency of single-junction perovskite cells reaches 33%, and laminated perovskite cells can be further improved to 45%. At the same time, perovskite, as a platform technology, can be combined with N-type TOPCon, HJT batteries, etc., to form crystalline silicon-perovskite stacked batteries, which brings a broad space for development. In 2024, perovskite battery modules will usher in several GW-level projects, and the commercialization process will continue to accelerate. According to the forecast of the China Photovoltaic Industry Association, by 2030, the penetration rate of perovskite photovoltaic modules in China is expected to reach 30%, and the market size is growing rapidly. However, perovskite battery modules still have some problems such as short life, poor stability and high difficulty in large area preparation.

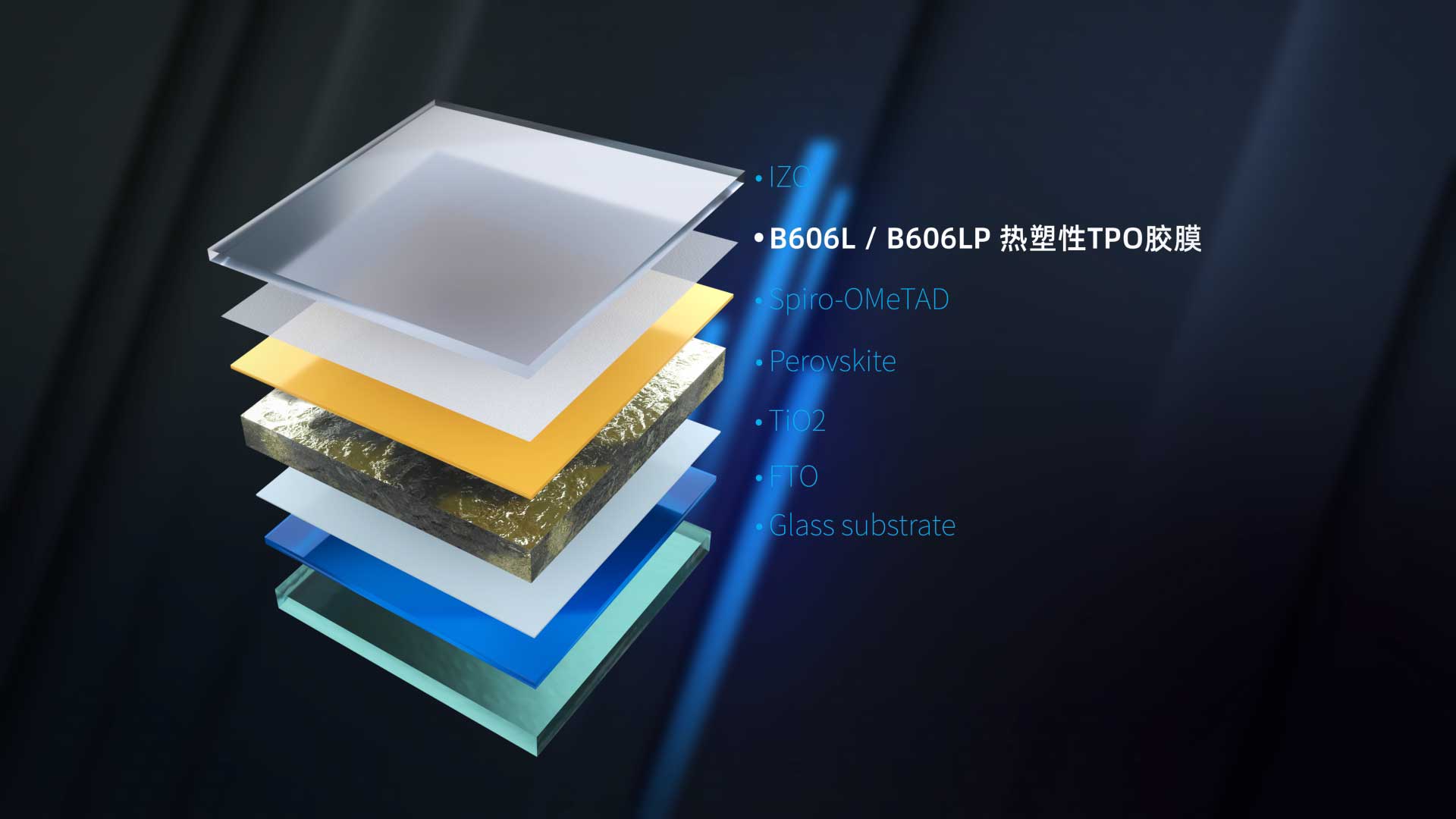

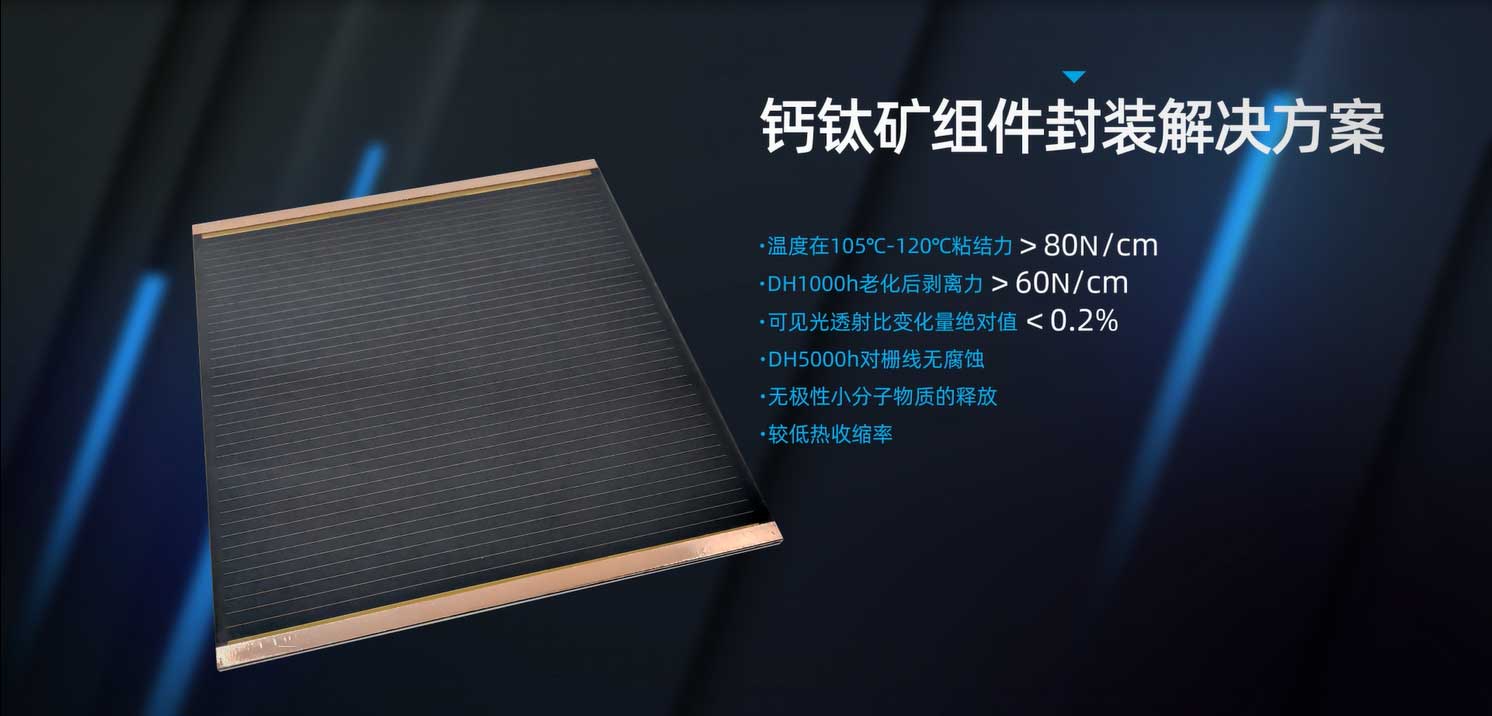

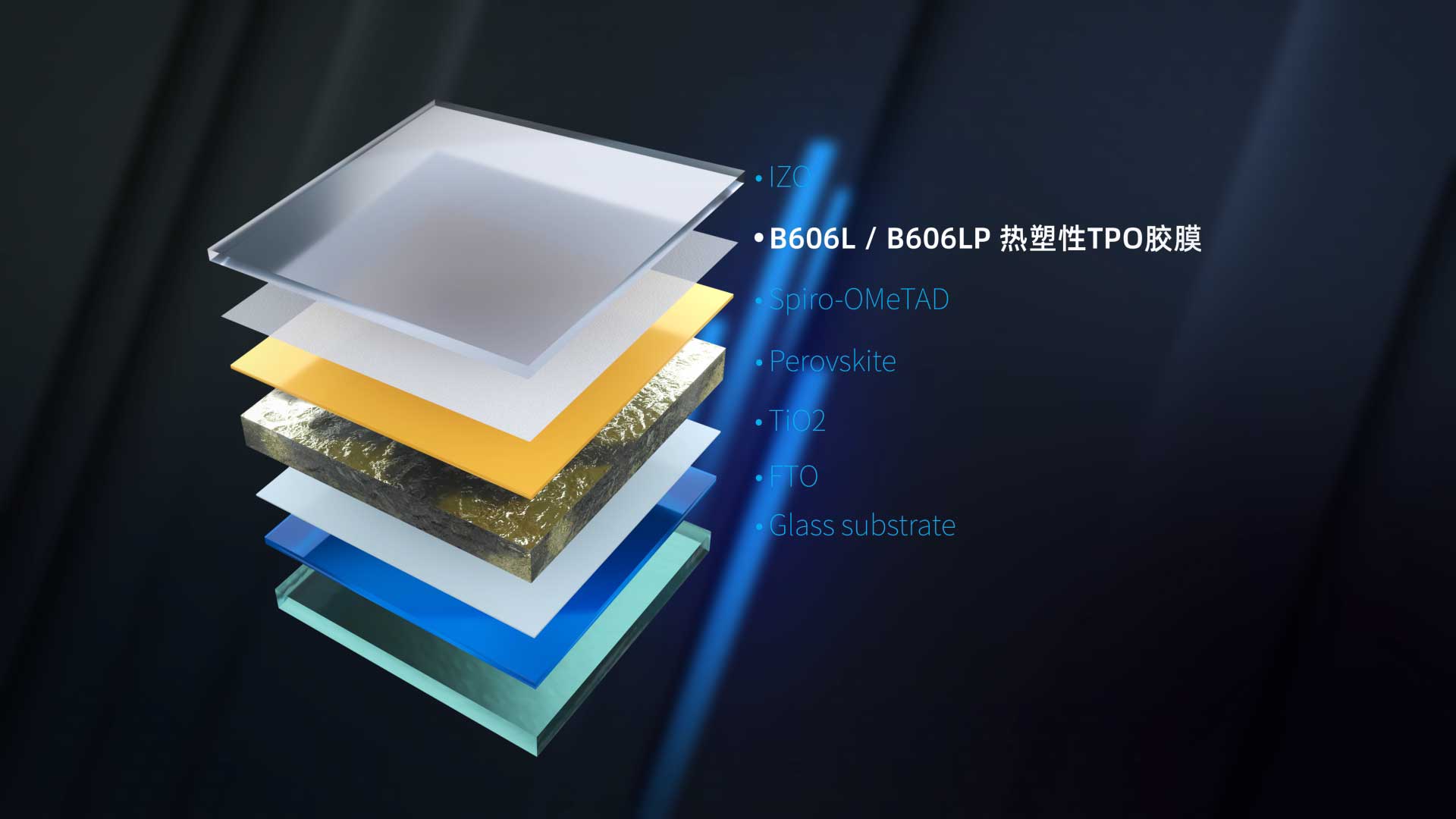

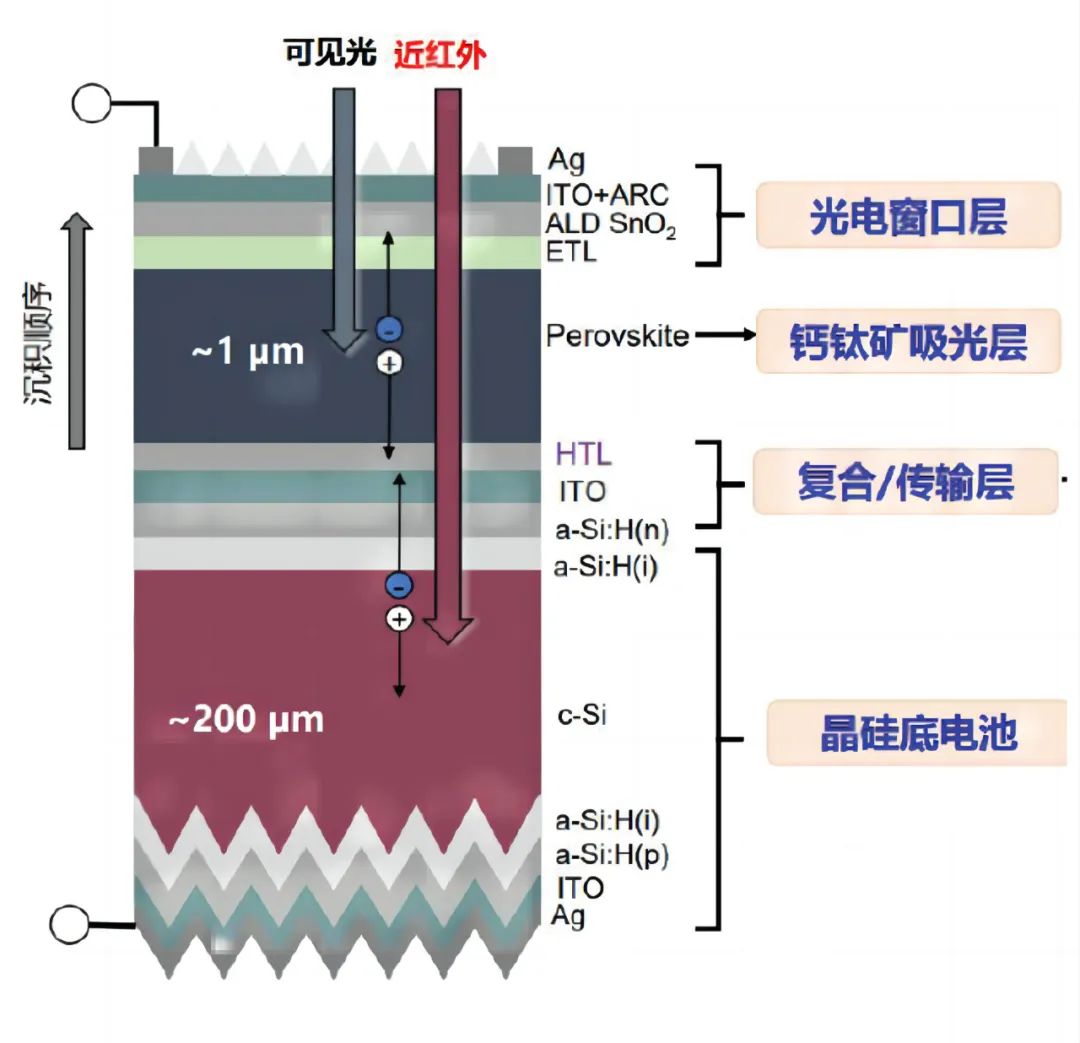

From the perspective of battery structure, the stability problems of perovskite batteries are mainly concentrated in the light-absorbing layer, the electron transport layer and the electrode material. Under high temperature, humidity, oxygen and other conditions, perovskite is easy to react with acidic substances, peroxides and polar small molecule substances, which will not only destroy the passivation effect of the interface layer, but also may lead to the change of perovskite crystal type, and eventually cause irreversible attenuation of battery power generation performance. Therefore, in order to ensure the stability of perovskite battery modules, it is necessary to choose a suitable encapsulation scheme. In the packaging of crystalline silicon battery modules, two layers of EVA film are usually used to achieve the bond between the battery and the glass and the backsheet. However, for perovskite battery modules, due to the EVA film will release a small amount of acetic acid during the aging process, which is corrosive to perovskite materials and may lead to reduce battery performance, so it is not possible to use conventional EVA film for encapsulation. As the first company in the industry to achieve small batch delivery of perovskite film, Betterial began to study perovskite packaging technology as early as 2018, according to relevant personnel, "compared with conventional EVA film, thermoplastic TPO film has the advantages of low encapsulated temperature and low water vapor transmission rate. And maintain excellent weather resistance and good adhesion under low temperature encapsulated conditions. The thermoplastic TPO film launched by Betterial has been supplied to head perovskite module companies such as GCL and Ningde Times in 2021, taking a leading position in technology."

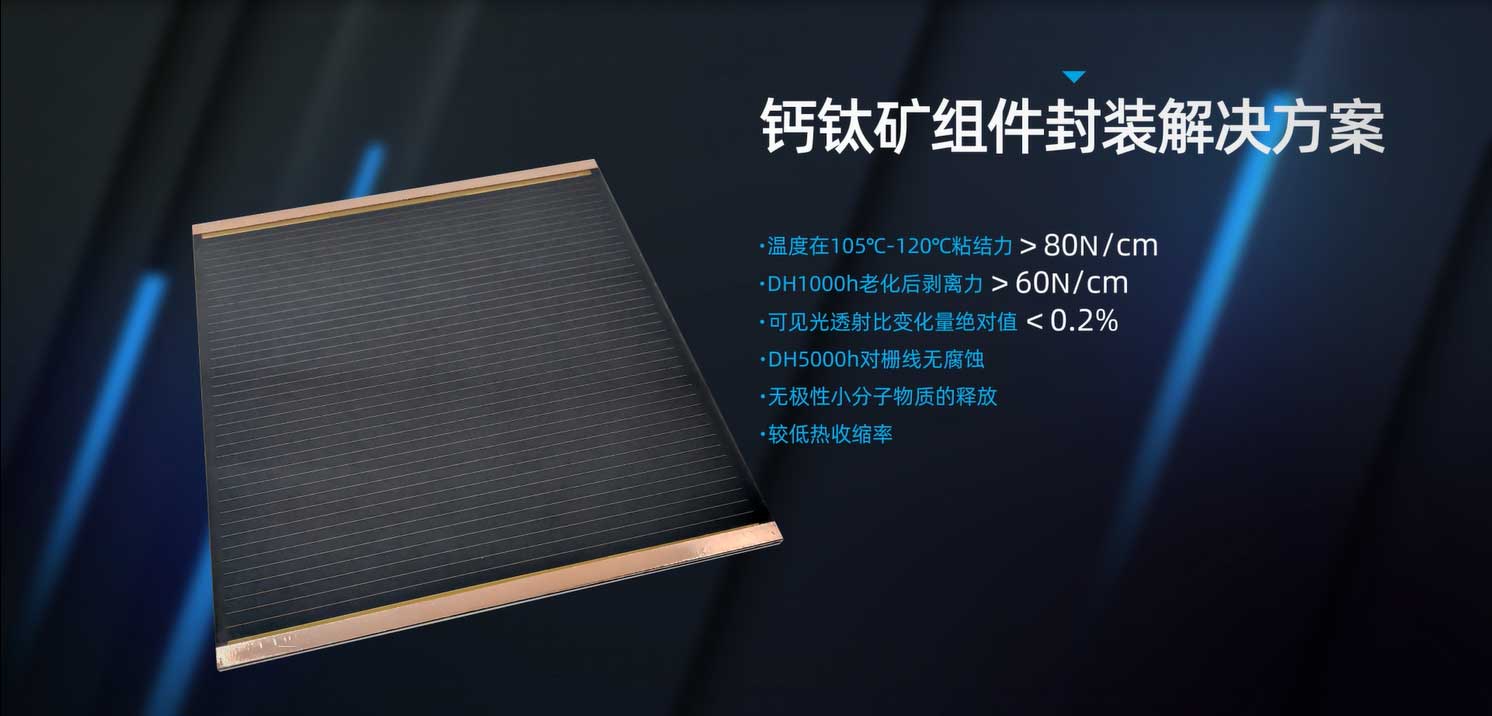

Not long ago, at the "2024 AIPV Digital Intelligence Conference" organized by Jiangsu Photovoltaic Industry Association, Dr. Xiong Weicheng, Chief Technology Officer of Betterial, was invited to attend and demonstrate the latest high-reliability encapsulation technology applied to perovskite and laminated perovskite modules. At the meeting, Dr. Xiong Weicheng especially introduced the new generation of perovskite special film, which adopts a unique recipe, through polymerization grafting and nanointerconnection technology, to achieve low temperature rapid lamination after high stripping force, while solving the problem of polar small molecule residue and long-term storage performance attenuation.

The new generation of perovskite special film can play a better role in protecting sensitive laminated batteries and provide more support for the stability of perovskite and laminated perovskite modules. At present, the film products have passed the National Inspection Center, Suzhou Meihua and other third party testing certification, and with GCL, Xiona, Jidian, Wandu and many other head perovskite enterprises for technical docking and sample, with Longi, Trina, Yaoneng and other customers in the encapsulation of new layered perovskite batteries for technical cooperation.

Cost reduction and efficiency "tool", perovskite high reliability encapsulation technology

It is worth mentioning that in the cost of perovskite modules, the cost of encapsulant film accounts for only 11 to 16.4%, but it is a key material that affects the quality and life of modules. By introducing innovative technologies and improving the encapsulation process, it can provide strong support for the cost reduction and efficiency of perovskite module products and further promote the development of its industrialization process.Since its establishment in 2007, Betterial has been deeply engaged in the functional film industry for more than 17 years, successfully opening up a number of technical links in the field of photovoltaic encapsulation materials. Relying on a mature technology platform, Betterial can provide customers with customized product solutions to meet the application needs of different scenarios. The company's photovoltaic film planning capacity has exceeded 130GW, and has established five production bases in Changzhou, Yancheng, Xianyang, Chuzhou and Vietnam, with long-term shipments ranking at the forefront of the industry.

At present, Betterial is working with leading enterprises in the industry to conduct national research on new perovskite technologies and perovskite demonstration projects, and actively lead the drafting of technical standards related to perovskite encapsulation to promote the standardized development of the industry. In the future, we will continue to strengthen the R&D and innovation investment in new products and technologies, further optimize the product structure, and make every effort to accelerate the cultivation and forging of new quality productivity, so as to export products with higher stability, lower cost and more advanced technology to the market, and continue to help the industry reduce costs and increase efficiency.