Parknshop Era comParknshop Era composite border

Reducing cost and increasing efficiency is the main theme throughout the development of photovoltaic technologyAll links of the industrial chain continueThe focus of attention. Photovoltaic composite borderCompared with the traditional aluminum alloy frame,possessmechanicsHigh strength,Excellent weather resistance, strong insulation, low material cost, light and beautiful features, in recent years, the industry has been concerned. For composite border technology needs,Parknshop targeted the launch of composite border weatherproof paint, the paintIt is not only green, but also has excellent weather resistance, UV resistance, salt spray resistance, corrosion resistance, wear resistance, scratch resistance and other characteristics.It is suitable for complex and diverse application scenarios in high temperature, high humidity, high salt spray, wind sand and other environments, providing strong support for the composite frame to open up a broader application market.

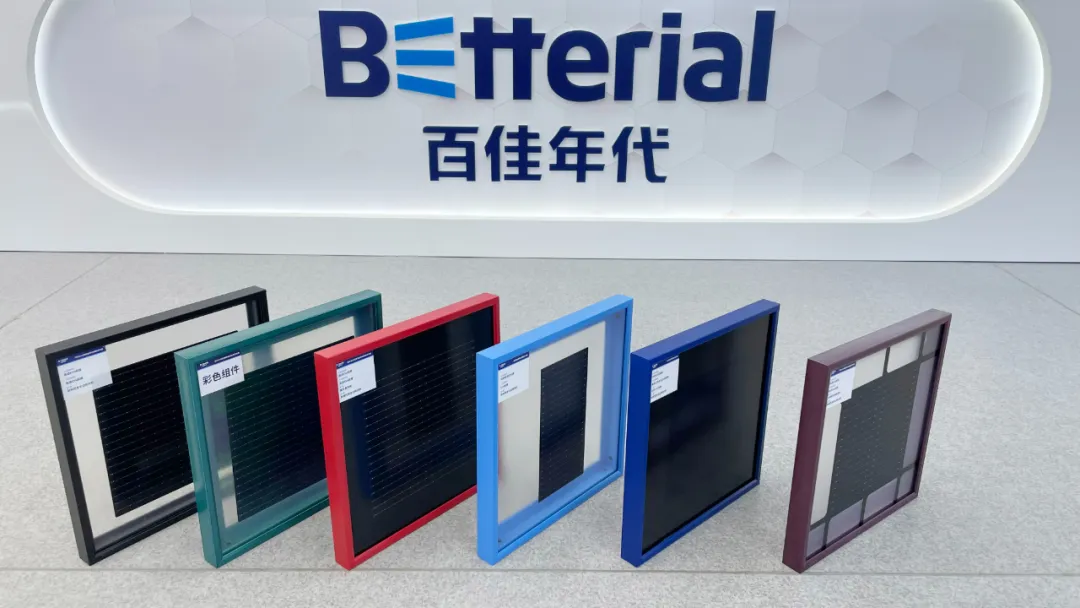

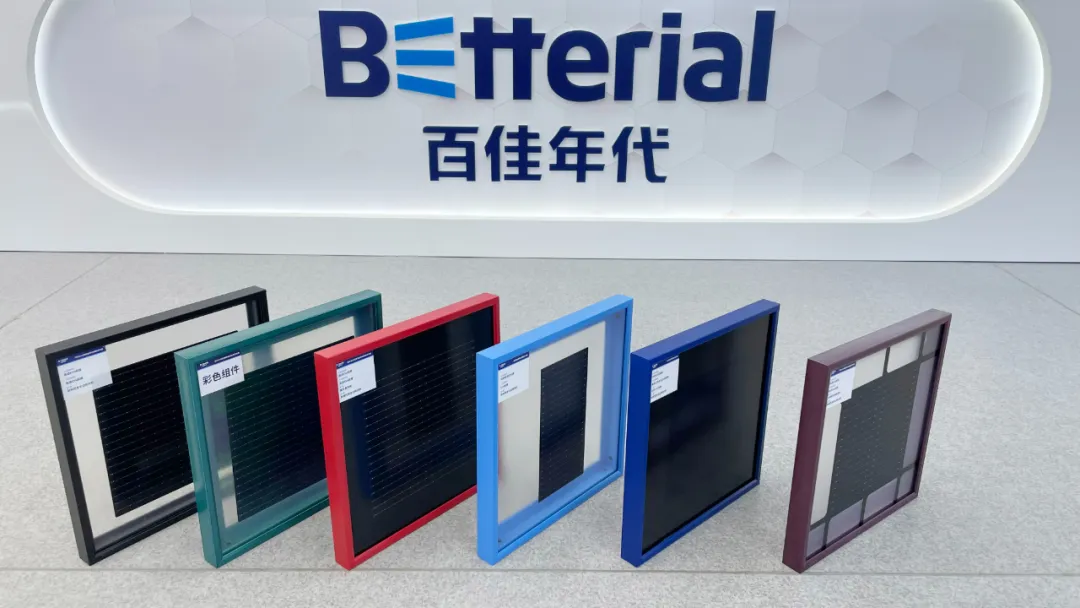

Green, beautiful and diverse

Parknage composite border weatherproof coating adopts water-based formula, the product is green and environmentally friendly, and the VOC content is far lower than the national standard, effectively reducing the impact on the environment. At the same time, the paint also has the characteristics of color diversity, no additional cost, to meet the diversity of customers and personalized use needs.

Excellent product performance, support more scenarios

In terms of performance testing, Parknshop Era composite border weather resistant coatings perform well. After wet UV 300kwh test, the coating color difference is small, light retention is high, no obvious powder phenomenon, showing its excellent UV resistance and aging resistance. Under 5000h, DH3000h and 2000 cycles of neutral salt spray, the appearance and performance of the coating have no change, which proves its excellent weather resistance and salt spray corrosion resistance. Drop sand test >8L/um, coating scratch hardness >2H, showing its excellent scratch resistance and wear resistance. Rigorous test results show that the product can support the stable operation of composite frame products in harsh environments such as oceans, lakes and deserts.

Perfect repair program, system to solve customer pain points

Taking into account the various situations that may be encountered in practical applications, Pajas has also introduced perfect repair solutions, products with UV light curing anti-slip strip and UV repair coating solutions, which can be quickly repaired in the customer's site, systematically solving the pain points such as easy scratching of the border stack and difficult repair after bumping and scratching. It provides a more convenient and efficient product experience for customers with composite borders.